Products >> Motorized Pinch Valves >> Proportional Pinch Valve

PPV25V Four-wire Control Normally Open or Closed Electric Proportional Pinch Valve

- Product No.:2023331172522

PPV25V Four-wire Control Normally Open or Closed Electric Proportional Pinch Valve

Introduction

The new series (ThinkvastTM) includes Motorized PVM Pinch Valve and PPV Proportional Pinch Valve, both of which use motor to drive the movement of the spool, and the operation is stable and the current is small.

PPV series electric proportional pinch valve can steplessly control the opening and closing degree of the pinch valve, and precisely control the liquid flow in the hose. The circuit adopts a four-wire system, the two power lines can use an ultra-wide supply voltage range, and the two control signal lines control signals according to the opening and closing degree of 0-5V or O-20mA.

The built-in position feedback of the PPV proportional pinch valve can precisely control the opening and closing degree of the hose, and at the same time, the unique non-linear driving method can facilitate the user to control the flow in detail.

PPV25V Series

1. Motion principle

The PPV series integrated electronically controlled proportional pinch valves use electronic components such as internal angle sensors and motor motion control circuit boards to control the motor without an external controller.

2. Control method

The PPV series integrated electronically controlled proportional pinch valve is a four-wire system, with two power lines and two control signal lines to control the opening and closing degree. The closed-loop control method can control the movement of the motor more effectively, avoiding problems such as motor step-off and unreliable control of the opening and closing degree. The newly upgraded built-in hardware PID controls the rotation of the motor and includes a braking mechanism to achieve precise positioning and responsive effects, and to precisely control every drop of fluid.

3. Voltage range

It has a built-in power management module, which can accept an ultra-wide voltage range of 9V~24V, and the control signal can accept 0-5V.

4. Size

The PPV series currently only has 25-types, corresponding to a maximum clampable tube outer diameter of 7mm. The Model 25 has a standard head diameter of 1 inch for easy replacement installation on existing proportional pinch valves. At the same time, the PPV series electronically controlled proportional pinch valve provides a variety of installation methods and installation accessories, which is convenient for customers to design and integrate.

5. Powerful thrust

This series adopts a special cam and rolling bearing drive structure, and uses a motor with a reduction ratio of up to 1000 times. The stable and powerful thrust calmly copes with the rebound force of the hose during clamping, making each clamping movement more reliable and stable.

6. Smart adjustment

Inherited from the latest PVM series, the PPV proportional electric pinch valve includes a dial mechanism, which can easily adjust the initial position of the moving slider, and is flexibly applicable to hoses of different wall thicknesses.

Specifications

|

Models |

PPV25VO |

PPV25VC |

|

Control method |

Four-wire system, two power lines, two control signal lines to control the degree of opening and closing |

|

|

Tube No. |

1 (Single) |

|

|

Initial state |

Fully Open when 0V |

Fully Closed when 0V |

|

Tube OD range (mm) |

Max 7mm |

|

|

Tube wall range (mm) |

0.5~2mm |

|

|

Clamping gap adjustment (mm) |

0.5~2mm |

|

|

Movement stroke of spool (mm) |

5mm, positioned proportionally with the analog control signal |

|

|

Supply voltage (V) |

9~24v |

|

|

Maxi instantaneous power (W) |

1.5W |

|

|

Control signal |

0~5V |

|

|

Input resistance |

100Kohm |

|

|

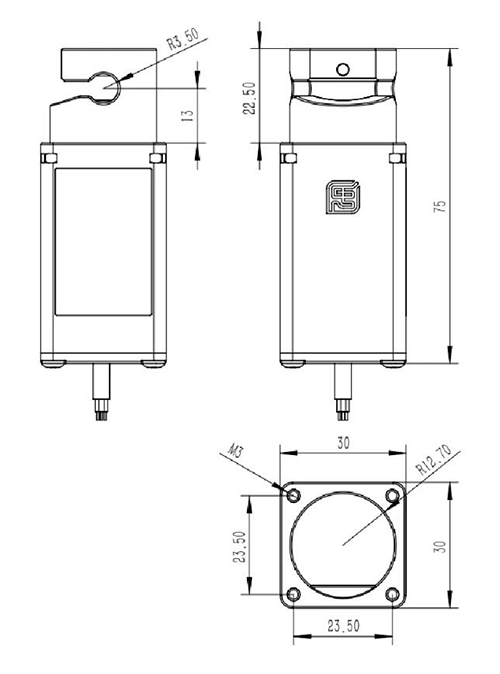

Dimensions (without cables) |

30mm×30mm×75mm |

|

|

Cable Specifications |

AVVR 4 x 0.2mm² |

|

|

Cable length |

1m (customized) |

|

|

Wiring |

Red V+, black V-, yellow controls positive, green controls ground |

|

|

Installation |

The valve body comes with 4 shoulder mounting holes and m3 nuts, the hole distance is 23.5mm |

|

|

Attachment |

Mounting flange, Side mount |

|

Dimensions and Drawings

Products Category

Contact Us

Name: Tony Zhao

Tel: +86-152 2168 4502

E-mail: info@oriwen.com

Skype: zhaodongxu1990@126.com

WeChat: +8615221684502

Whatsapp: +8615221684502

Add: 5th F, Bldg 7#, No.7001 Zhongchun Rd, Minxing Dist, Shanghai, 201101, P. R. China.

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry