Products >> Electric Rotary Valves >>

ZS20 Ceramic Body and Core 10 Ports Switching Valves

Oriwen Fluidics Mini ZS20 series of electric rotary valves (multi-port dispensing valves) use encoders to collect signals and rely on stepping motors for control. They are widely used in automatic parts for sample collection, liquid injection or flow conversion.

Features

1. Ceramic valve body: Ceramic is processed as a whole, with less residue and high strength.

2. Driver integration: The valve body motor control circuit is integrated internally, and the host can communicate with the controller through RS485/RS232 protocol.

3. Resistance to strong chemical corrosion: Only the valve body and valve core are in contact with the medium. The valve body and valve core use alumina ceramics, which can be applied to various corrosive liquids.

4. Wide selectivity: switching valves with various hole positions from 6 to 10 holes are available.

5. Sealing method: The stator and rotor are closely matched to achieve the highest service life and excellent sealing.

6. Driving mode: planetary reduction mechanism, greater driving force.

7. The valve hole positioning adopts optical encoder positioning, which can effectively solve the problem of inaccurate positioning after the reduction box is worn;

8. Precise position feedback, feedback position information calculated through encoder

9. Jam information feedback

10. Provide convenient configuration software tools to facilitate parameter configuration and debugging.

Specifications

|

Valve body/core materials |

Ceramic |

|

Stator Form |

Inclined |

|

Flow Path Structure |

3, 4, 6, 8, 10 way |

|

Flow Path Orifice Size |

1.2mm |

|

Applicable |

Various highly corrosive chemical media |

|

Thread Connector |

1/4’’-28UNF |

|

Dead volume (port to port volume) |

2~4ul |

|

Work Pressure |

Air pressure 0.5Mpa Water pressure 1.0Mpa |

|

Leak rate |

0 |

|

Ambient temperature |

Max 60℃ |

|

Medium temperature |

Max 150℃ |

|

Relative humidity of environment |

<80% |

|

Switching speed |

4S/turn |

|

Voltage |

24 VDC |

|

Current |

1 A |

|

Power |

24W |

|

Communication Protocol |

RS485/RS232 |

|

Communication Rate |

9600bps (default, modifiable) |

|

Dimensions |

61.5x62x102mm |

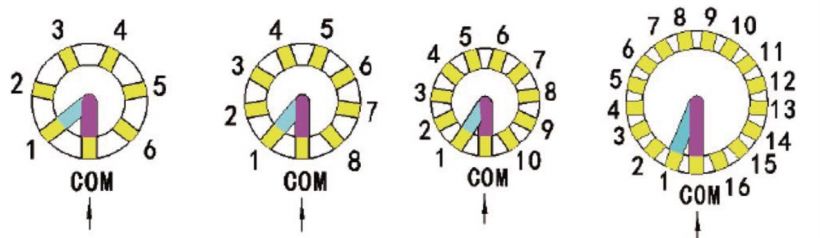

Port Selection Mode (Switching)

The COM end is a public channel, selectively connected to ports 1 to 10 or 16.

(*Pictures only for reference)

*Liquid path selection and mixing, for example, the same liquid flows to different ports to achieve the distribution effect, or multiple liquids flow to the outlet together to achieve the mixing effect.

Feel free to contact us for quotation of new series Electric Rotary Valve.

Products Category

Contact Us

Name: Tony Zhao

Tel: +86-152 2168 4502

E-mail: info@oriwen.com

Skype: zhaodongxu1990@126.com

WeChat: +8615221684502

Whatsapp: +8615221684502

Add: 5th F, Bldg 7#, No.7001 Zhongchun Rd, Minxing Dist, Shanghai, 201101, P. R. China.

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry