Products >> Micro Pump >> Micro Gear Pump

Whole Set A500S-4N Micro Pump

-Suitable for high pressure and low flow occasions

Product Structure Features

1. Stainless steel shells, obvious corrosion resistance

2. Gear material is the modified PEEK, which is recognized as high-quality, expensive and wear-resistant material superior to metal, and ultra-quiet.

3. Teflon static seal, no leakage; EPDM seal at the interface, fluororubber and Teflon optional.

4. Rare earth rotor, brushless motor, built-in controller, compact size, total weight about 0.7Kg.

Product Parameters

1. The standard power of the motor is 40W. Intermittent working conditions allow 55 watt work; three-phase brushless motor.

2. Motor speed ranges 0-5500 RPM.

3. Standard working voltage, DC24V. (Allowable maximum 36V) Control voltage 0-5V (control pump flow, pressure).

4. Speed pulse feedback and shielding protection.

5. Motor housing is aluminum, including product mounting bracket, aluminum, screws, etc.

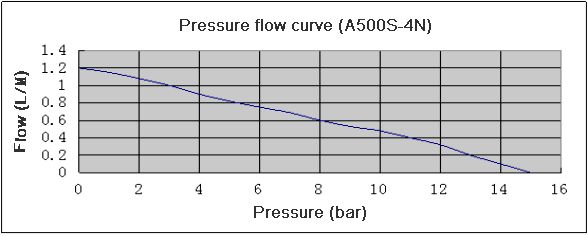

6. Flow range 0-1.2 L/M (liters/minute), pressure output range 0-15 Bar. If working continuously, the recommended working pressure is less than 0.6MPa.

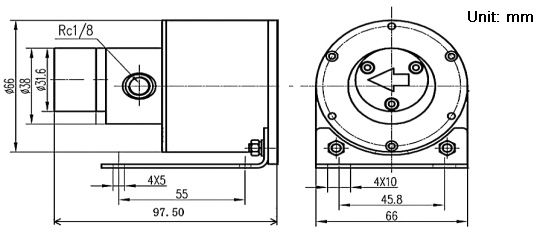

7. Pump head interface: rc1/8, connection size (OD x ID mm) 4x2.5, 6x4, 8x6 Teflon tube recommended (optional). Standard quick connector.

8. Transport media: almost all media except strong acids and bases.

9. The viscosity range of the conveying medium: less than 1500cps.

Installation dimensions

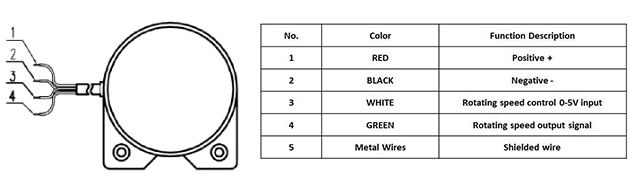

Typical Control (Standard)

The motor is based on a brushless Hall motor, and the controller is built in one, thus greatly reducing the volume of the pump. A 0-5 volt Dc signal can control the pump pressure/flow rate from 0Bar/0mL to the maximum pressure. This greatly reduces the troubles of OEM equipment suppliers in circuit design and control.

*Description:

1. The external speed control line (white) 0-5VDC signal can realize the change of flow rate and pressure 0-Max. It can also cooperate with pressure sensors, potentiometers, PLCs, industrial control boards, etc. to deliver liquid or generate pressure in dynamic, static, continuous or intermittent ways.

2. For customers who use a potentiometer to control the speed, a yellow wire is added on the basis of this 5 signal line to provide a 5Vdc basic speed regulation signal, and the potentiometer is used as a speed control signal power supply (need to explain when ordering).

3. For users with forward and reverse requirements, the yellow wire is grounded (low level), which can control the motor's forward and reverse function, so as to realize the positive and negative flow function of the pump medium (need to explain when ordering).

Flow Pressure Curve Characteristics

Installation and Use

1. The direction of the arrow marked on the pump head is the correct flow direction of the medium. The arrow indicates the positive pressure direction, and the other end is the negative pressure. During installation, the three flange screws of the motor can be removed to change the installation direction of the pump head.

2. Before selecting the pump head, please confirm the medium type: solvent-based medium or Suspension medium? The pump heads used for these two media are different. If it is a suspension, an alloy gear pump must be used, such as a tungsten steel gear, and a solvent type is not necessary. Engineering plastic gears are sufficient.

3. Whether the medium has impurities. Our gear pumps are extremely precise, so no obvious impurities are allowed in the medium. If it cannot be avoided, a filter must be installed on the suction side of the pump, which is available from our company, please consult with the sales or technical staff.

4. The pump should work under the appropriate working pressure, overload work will quickly reduce the pump life. Our company has pumps with multiple pressure ranges, please consult with technical personnel when purchasing.

5. After the pump is removed from the pipeline, please close the inlet and outlet, and do not expose to the air, otherwise, the medium will easily cause the pump head to be stuck after volatilization!

6. Before connecting to the power supply, please carefully check whether the signal cable is connected correctly. Wrong connection to the power supply can easily burn the motor!

7. The pump should work at a suitable ambient temperature. In principle, the ambient temperature should not exceed 40 degrees. If it cannot be avoided, please do good jobs of heat dissipation design.

8. The performance of the pump has been better when leaving the factory, please do not disassemble and adjust it yourself! Otherwise it will cause damage to the pump!

Hot Pinch Valve Products:

12VDC 3way Pinch Valve 02T | 12VDC NC Pinch Valve 05T | 24VDC NO Pinch Valve 05T

You may also be interested in:

WK Series Pinch Valve | Rotary Dispensing Valve | Solenoid Isolation Valves

Products Category

Contact Us

Name: Tony Zhao

Tel: +86-152 2168 4502

E-mail: info@oriwen.com

Skype: zhaodongxu1990@126.com

WeChat: +8615221684502

Whatsapp: +8615221684502

Add: 5th F, Bldg 7#, No.7001 Zhongchun Rd, Minxing Dist, Shanghai, 201101, P. R. China.

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry