Products >> Micro Pump >> Micro Gear Pump

ORIWEN New Stainless Steel Micro Metering Gear Pump

The magnetic drive gear pump uses a 316 stainless steel shell, a PEEK gear, and a PTFE sealing material. Powered by a brushless DC motor, the shaft end of the motor is connected to the outer magnetic ring of the rare earth permanent magnet to drive the magnetic gear pump to achieve smooth delivery of liquid without leakage or pulsation. Its advantages are simple structure, small size and large torque. The motor speed can be adjusted by changing the voltage to achieve flow control.

Features

. The model is small in size and compact in structure.

. PEEK gears and bushings are oil-resistant, heat-resistant, corrosion-resistant, and high-strength and friction-resistant.

. Silent, low voltage to avoid unstable operation, small size and light weight.

. The flow rate is fixed and cannot be adjusted.

. Intermittent work

. The brushless motor can work for about 20,000 hours, and the normal service life is 7-10 years.

. Safety and environmental protection levels can meet international standards (CCC, ROSH, CE)

Technical Parameters

|

|

Description |

|

Model |

ORISGE0.6DCI57-24-60W |

|

Displacement |

0.6ml/rev |

|

Flow |

0-3L/min |

|

Pressure |

3bar |

|

Motor |

57 Brushless DC motor |

|

Speed |

0-6000rpm |

|

Power |

60W |

|

Voltage |

24V |

|

Current |

1.4A |

|

In and out direction |

Both sides of the pump body |

|

In and out thread |

G1/4 |

|

Temperature resistance range |

-10-120℃ |

|

Noise |

45dB |

|

Material |

Pump body 316L, alloy, sealing ring PTFE, gear PEEK |

|

Insulation level |

H |

|

Drive mode |

Magnetic drive |

|

Way of working |

Continuous |

|

Service life |

20000-30000H |

|

Viscosity range |

0-1500cps |

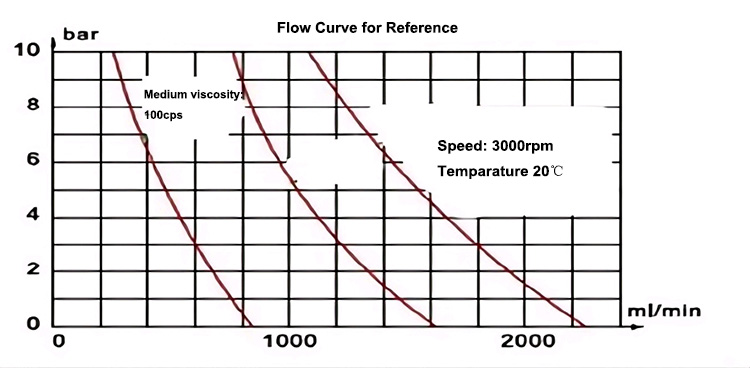

Flow Curve

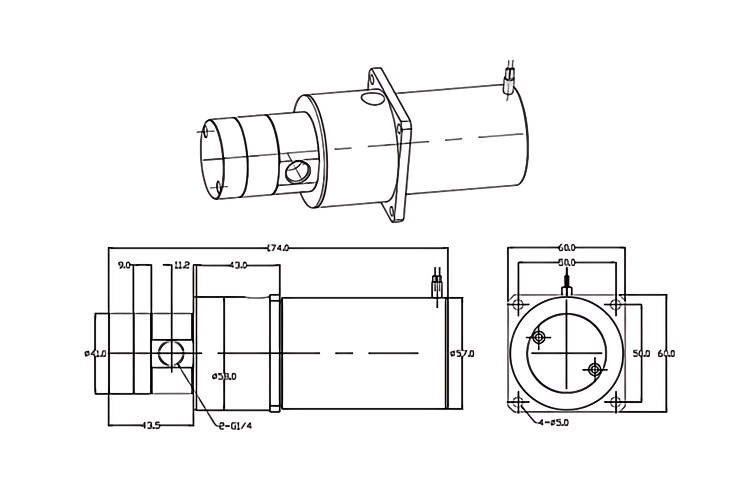

Installation Dimensions

Application

Coffee machines, ice cream machines, inkjet printers, inkjet printers, printing machines, packaging, filling machines, food processing, vending machines, hemodialysis machines, water purification, cleaning, laboratory equipment and medical equipment, etc.

Precautions

1. It is strictly prohibited to transport or clean solvents and materials containing dichloromethane, tetrahydrofuran, butyllithium, and dimethylacetamide.

2. Before disassembling the pump, please cut off the power supply to the motor and completely release the pressure in the pump.

3. Do not change the components of the pump and motor. Any changes may reduce the pressure rating of the pump and cause harm to people.

4. A sealing ring, sealant or raw material tape must be placed on the inlet and outlet joints of the pump, especially at the inlet. If there is air leakage, the liquid will not be sucked, and the noise will even increase.

5. It is prohibited to transport media containing particles, and it is prohibited to run idling/dry.

OEM service is available upon your request.

Hot Pinch Valve Products:

12VDC 3way Pinch Valve 02T | 12VDC NC Pinch Valve 05T | 24VDC NO Pinch Valve 05T

You may also be interested in:

WK Series Pinch Valve | Rotary Dispensing Valve | Solenoid Isolation Valves

Products Category

Contact Us

Name: Tony Zhao

Tel: +86-152 2168 4502

E-mail: info@oriwen.com

Skype: zhaodongxu1990@126.com

WeChat: +8615221684502

Whatsapp: +8615221684502

Add: 5th F, Bldg 7#, No.7001 Zhongchun Rd, Minxing Dist, Shanghai, 201101, P. R. China.

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry